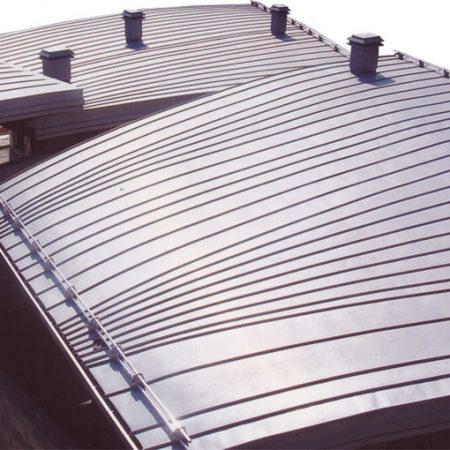

Batten standing seam metal roofing

A longitudinal rib well marked for aesthetic characteristics of particular value

The corrugated roofing is carried out through the application on the structure of previously corrugated sheet metal panels, so as to create, after installation, a particularly marked longitudinal repeated ribbing.

The dimensions of the ribs and their center distance are determined according to the wind stresses, the inclination of the roof; the aesthetic characteristics that the covering must present at the end of the work are also considered (divisions and cadence of spaces and surfaces that are not random but designed).

The execution is carried out by fixing with concealed dowels that find anchoring on the substructure, designed and performed in order to eliminate any infiltration.

An aesthetically distinctive roofing is generated, that gives a sense of modern solidity and strength to the protected structure; especially suitable for constructions with a modern architectural setting.

-

-

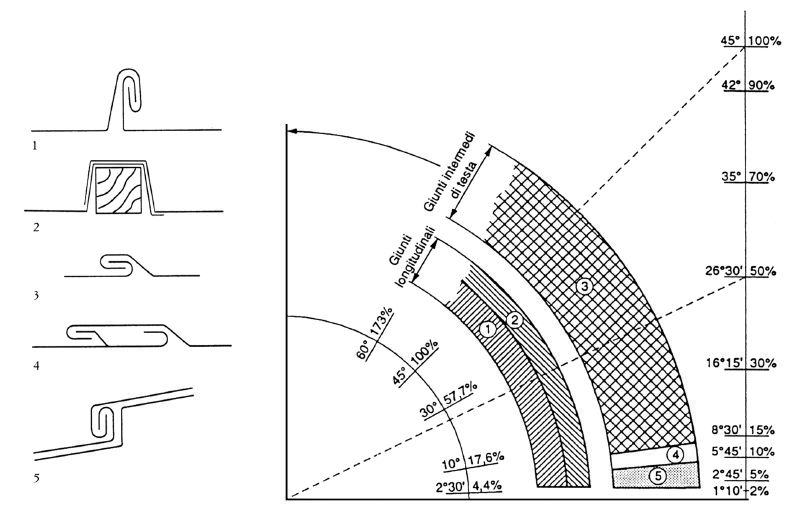

Slope

The type of roofing that can be applied varies according to the slope of the substructure and the method of making the same copper (metal) roofing.

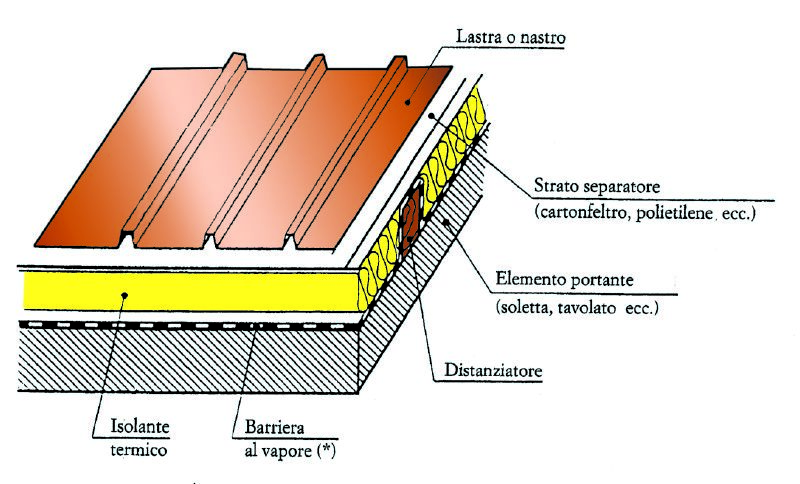

Not ventilated insulated roofing

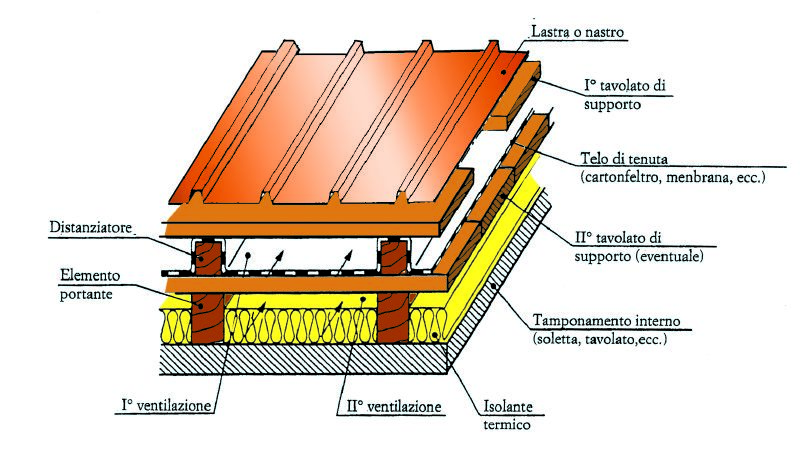

In single ventilation, the sealing sheet is positioned below the insulation, the load-bearing element is replaced by the spacer and the second plank is eliminated.

Double ventilated insulated roofing

The support element or the laying surface can be made up of wooden planks, a concrete floor or a brick and cement ceiling suitably prepared and insulated on our instructions.

-

Lightness as anti-seismic construction criterion

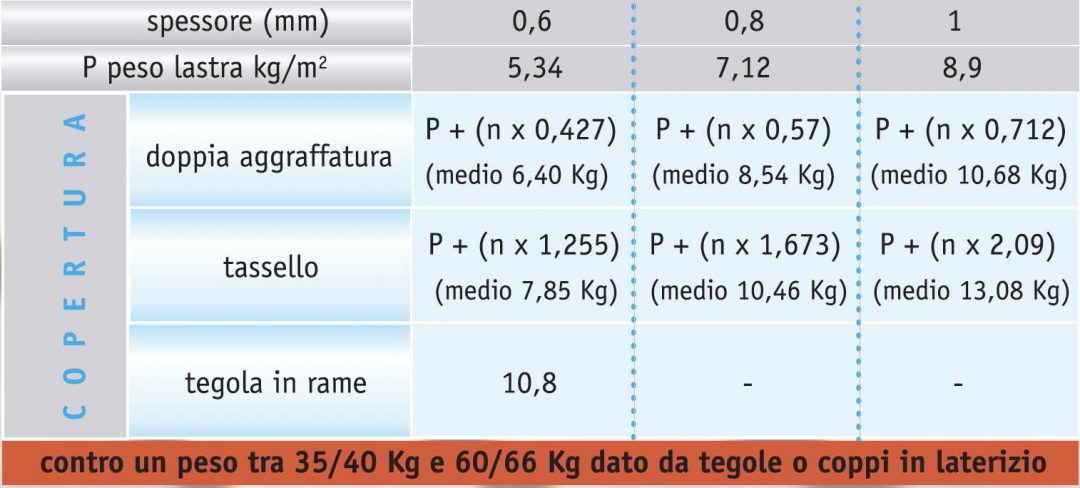

COPPER ROOFING WEIGHT TABLE

during an earthquake the stressing force F = m (mass) x a (acceleration),

therefore by halving the mass, and therefore the weight of the roofing, the stress that the structure must undergo is halved; the weight of a copper roofing is up to 10 times less

P = metal roofing sheet weight

n = number of subdivision spaces per meter

Consult the Technical Office

-

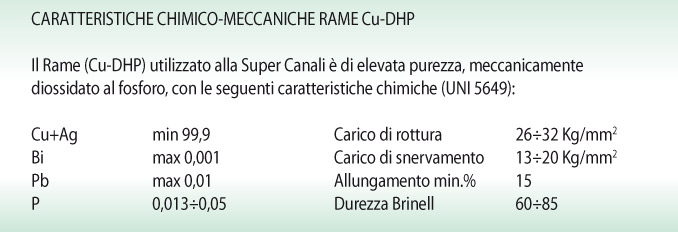

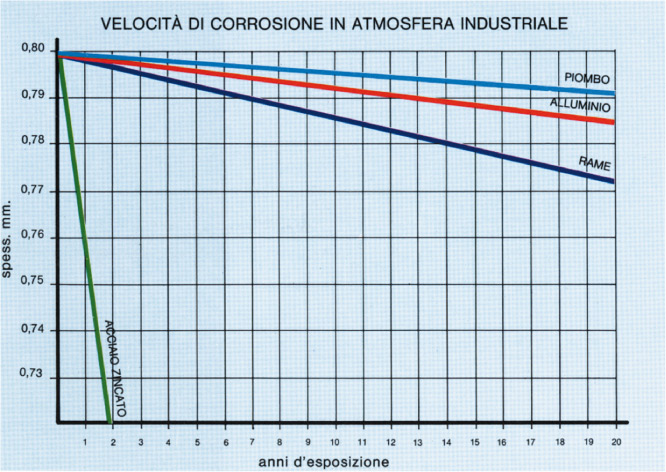

THE LONG LASTING TIME AS ECONOMIC SAVING

Thickness and quality of the material, width of the panels and frequency of the fixing points are set according to the wind load. The installation is carried out in such a way as to respect the mechanical requirements of the material and the expansion of the same, avoiding the formation over time of tearing or breaking triggers. To complete the work, all the tinsmithery and accessories for water disposal are carried out for a guaranteed turnkey metal roofing against infiltration. The same technology is applied with the use of other materials such as lead, aluminum, zinc-copper-titanium alloys, stainless steel, zinc.

-

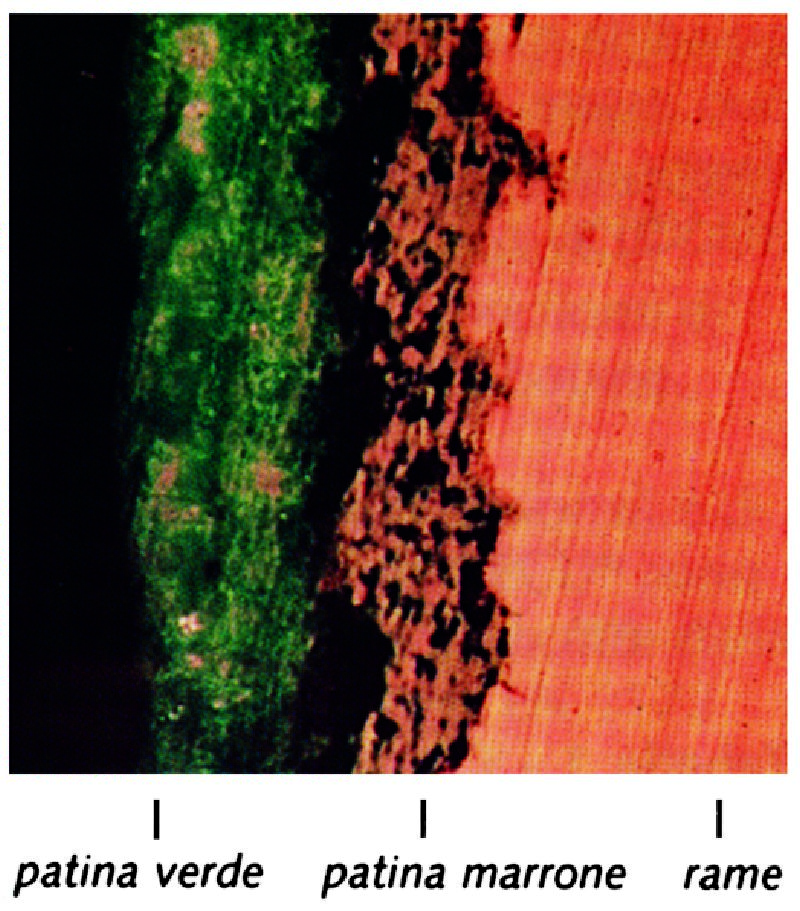

Aged copper

Copper as roofing material has no need of presentation: lightness of the covering, pleasant appearance and aesthetic finish of its oxidized color, longevity of the supplied and waterproofing characteristics, reduction over time of roofing maintenance costs; makes it a building technology element of the highest value and with no equal, both for residential and commercial buildings, both modern and of the past.

Copper as roofing material has no need of presentation: lightness of the covering, pleasant appearance and aesthetic finish of its oxidized color, longevity of the supplied and waterproofing characteristics, reduction over time of roofing maintenance costs; makes it a building technology element of the highest value and with no equal, both for residential and commercial buildings, both modern and of the past.

The opening towards new applications and solutions of materials has suggested to Super Canali the introduction of ” aged copper”.

It is first quality copper subjected to a suitably developed mechanical-chemical-thermal process in order to make immediately available the exclusive green color of the oxidizing patina that would otherwise take several decades to naturally form on site.

In fact, copper in the natural process, a cause of the combined action of humidity, oxygen and polluting agents present in the air, is characterized by a first brown patina, which then changes to anthracite brown and then develops, in more or less time depending on the location, the characteristic final green patina, the unity of sulphates and basic copper carbonates.

With the choice of aged copper, a sure exclusive note is applied to each structure.

-